The Sound That Built the Craft

Posted on

From the bench of Brandyn Feldman – June 2025

There’s been a shift in the air lately. Machines are getting quieter, but so is the knowledge. Everyone’s chasing wireless, touchscreen-driven, cartridge-loaded, auto-tuning setups that promise more with less. Less mess. Less noise. Less involvement. But that trade-off comes at a cost.

I come from a school of thought that says the sound of a machine matters. That the hum of a dialed-in coil machine isn't just noise—it's information. It tells you about tension, timing, heat, and how deep you’re hitting. You take that away and what are you left with? A plastic shell that buzzes just enough to fake it.

These wireless pens have convinced a generation that convenience equals progress. That quiet equals clean. But the truth is, most of these machines are far from clean. You can’t sterilize what you can’t fully open. Internal components, non-autoclavable housings, motors sitting right behind open ports—those machines aren’t sterile. They just look sterile. That’s not progress. That’s packaging.

And if you’re not following real protocol—using an autoclave, ultrasonic cleaners, barrier wraps, and clean/dirty separation—you’re not protecting your work or your name. That’s the hard line. Always has been.

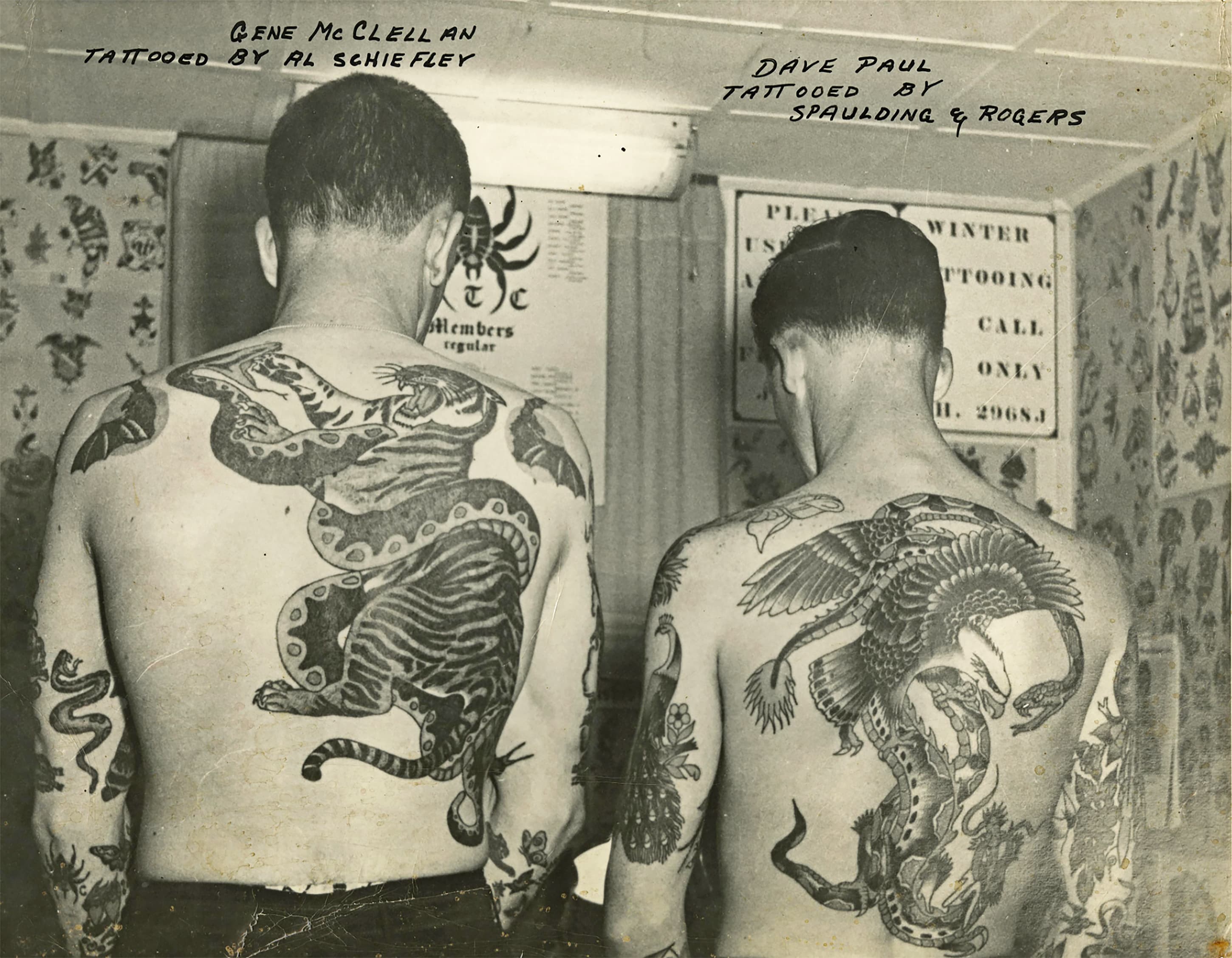

What keeps me focused is the work. The real work. I’ve spent years building machines and chasing that elusive “perfect hit.” The one that drives clean, heals smooth, and doesn’t fight the hand. And in that search, I found my roots in the same place as some of the best—builders like Paul Rogers, Norman Collins, and Des Connolly. Guys who didn’t wait around for answers. They made their own.

There’s a letter from Sailor Jerry from 1972 that sits at the heart of how I build. He wasn’t just drawing daggers and girls. He was obsessed with power delivery. Polarity. Coil response. The guy was breaking down electrical theory and applying it to frame geometry, core shape, spring behavior. That letter shaped me. Still does.

What I see now is a supply chain built to keep artists in the dark. And one major supplier—let’s just call it what it is—is rotten from the top. It’s run by people who don’t care about tattooing. They push product purely for profit, break laws like it’s routine, and even move gear to countries under embargo, using foreign cutouts to hide the trail. This isn’t rumor. It’s fact. And it’s happening while people are busy scrolling for sales.

That’s part of why I started Feldman Tool Co.—to carve a different path. I wanted to make tools that speak the language of real tattooing. That require understanding. That reward attention. We cut frames from steel, grind them flat, dial in the geometry, and test them until they respond. Our machines aren’t built for mass appeal. They’re built for professionals who still care about the tactile side of this trade.

If you’re serious about tattooing, you owe it to yourself to know what’s in your hand. Learn what makes a machine respond the way it does. Study stroke, voltage, throw, balance. Know your springs. Know your coils. Understand duty and lag. I’ll be publishing a blog soon that breaks down the basics of current and power delivery, because this isn’t gatekeeping—it’s empowerment.

Another thing worth doing? Keep a log. Track your tools. Write down your machine specs, voltage ranges, needles, tubes, pigments, and what worked—or didn’t. Over time, that kind of journaling creates a map. A pattern. And once you see the pattern, you can adjust it. That’s control.

Take the time to tear a machine apart. Learn to solder your own needles. Test setups, fail, and test again. It’s not about being old school—it’s about not being blind. No machine can replace your instincts if you build them sharp enough.

And here’s the truth: whether you love traditional tattoos or think they’re outdated—whether you obsess over old flash or couldn’t care less—if you put a needle into skin and care about doing it right, you’re part of a lineage. A lineage built on blood, craft, and resilience. It might just be the coolest job in the world.

So keep tuning. Keep learning. And don’t let silence fool you. Tattooing isn’t supposed to be quiet.

It’s supposed to hum.

– Brandyn Feldman

Contact

B@feldmantoolco.com